Automotive Connectors Manufacturer

A leading automotive connectors manufacturer was in need of a wastewater treatment system to address oil and grease and  heavy metal contaminants in their discharge. Based on understanding of the waste stream and ability to provide a cost effective solution, Dynatec was selected to provide a system that would produce effluent that reliably met the sewer discharge requirements. By using a combination of free oil separation and an Ultrafiltration Membrane system, in addition to removing all of the suspended solids, the Dynatec supplied system consistently provides the following effluent:

heavy metal contaminants in their discharge. Based on understanding of the waste stream and ability to provide a cost effective solution, Dynatec was selected to provide a system that would produce effluent that reliably met the sewer discharge requirements. By using a combination of free oil separation and an Ultrafiltration Membrane system, in addition to removing all of the suspended solids, the Dynatec supplied system consistently provides the following effluent:

Parameters Influent Effluent

Oil and Grease 1,100 <100

Zinc 2.4 <1.48

Chromium 3.2 <1.7

Automotive Solutions Provided

- Oil and metals removal

- Membrane Bioreactor (MBR) biological treatment

- MBR for water reuse of wastewater

- High purity reuse with MBR and RO

Complete purification and reuse of wastewater system solutions for many automotive firms were provided by Dynatec Systems for:

- Cooling tower makeup

- Irrigation

- Boiler feed

- Paint line

Contaminants Removed

- Oil and Grease

- Metals

- Suspended Solids

- Surfactants

- Biochemical Oxygen Demand (BOD)

- Chemical Oxygen Demand (COD)

- Dissolved Solids

Automotive oily wastewater treatment systems for many facilities in the automotive industry were designed and supplied by Dynatec Systems including the following:

- Stamping plants

- Powertrain plants

- Assembly plants

- Bearing manufacturer

Our customers include many large car and truck brands as well as suppliers to those manufacturers.

Ultrafiltration offers the following advantages over conventional separation:

- No chemical required

- Very little labor required

- Simple mechanical process

- Less sludge

- Ability to concentrate the retentate for beneficial use

- Less space required

- Overall lower operating costs

Tubular Configuration:

- Higher permeate rate

- Lower rates of fouling

- Higher concentration of retentate

- Easier to clean

- Longer membrane life

- Low operating cost

Ultrafiltration is a pressure-driven process that removes the following from wastewater and other solutions:

- Emulsified oils

- Metal hydroxides

- Colloids

- Emulsions

- Dispersed material

- Suspended solids

- Other large molecular-weight materials

Ultrafiltration systems are also capable of concentrating:

- Bacteria

- Some proteins

- Some dyes

- Colloidal or emulsified components

For more information, please contact us today.

https://www.dynatecsystems.com/technologies/recovery-and-reuse/

https://www.dynatecsystems.com/technologies/membrane-technologies/ultrafiltration-systems/

Dairy Converts System to MBR

A dairy converts an existing biological system to a membrane bioreactor (MBR). The converted plant has the ability to process wastewater at the rate of 475,000 gallons per day.

The conversion provided the ability to increase the treatment rate and at the same time improve the quality of the treated water. The system operated at a higher concentration of mixed liquor in the bioreactor and thereby increase the throughput capacity of the existing bioreactor and improves the quality of the treated water (0.03 micron membrane allows less bacteria and virus to penetrate the membrane surface) that is discharged.

The Dynatec “out of bioreactor” membrane configuration provided for optimization of both biological and membrane systems. Dynatec’s membrane system decoupled the membrane filtration and biological treatment in a way that allowed for optimization of both the solids liquid separation and the biological system design. The system is capable of operating with MLSS as high as 25,000 mg/L and this has maximized the operator flexibility in plant operations to achieve optimum performance. The positive recirculation through the membrane system minimizes fouling and reduces operator attention.

The amount of space required for the membrane system was small and therefore the system was easily added because of the flexibility in locating the membrane system. The system did not need to be next to or close to the bioreactor. The higher system membrane flux (permeate rate) meant that fewer membranes were required. The simple design required less ancillary equipment and operation at high MLSS meant that no additional tanks were required.

Dynatec’s membrane systems draws on our many years of experience to provide a cost effective, simple system that outperforms other systems, especially with difficult to treat waste streams.

Dynatec’s membrane system was selected in part because the overall capital cost was lower than alternative solutions and because the conversion was principally centered on the addition of the membrane system which was inexpensive to install and the location did not need to be close to the existing bioreactor.

Another reason for the selection of Dynatec by the dairy converts existing system to MBR was because the membrane systems are completely enclosed which minimizes maintenance and provides a safe, clean environment for operators. The operators were not exposed to fumes and noxious gases.

The system was designed for remote access on any device with a web browser enabling the operator to review system performance and make changes without a site visit.

The unique operation of the membrane system makes it the right solution for difficult to treat wastewater applications such as dairy wastewater. The membrane system operates using tubular membranes in series with a recirculation flow that continuously scours the walls of the membrane surface. This prevents the buildup of solids on the membrane surface. The elimination of the solids buildup on the membrane surface results in high flux rates and consistent, dependable operation even in difficult applications where the solids do not filter well.

Contact Dynatec to discuss your wastewater needs.

Reuse Water with MBR

High-quality discharge and reuse from MBR

Dynatec Provides Reuse Water for Cereals Plant

Dynatec Systems, Inc. has installed a water reuse system in a major cereals plant in Georgia.

The complete treatment system, consisting of a membrane bioreactor (MBR), followed by reverse osmosis (RO), provides a net savings to the plant of more than $3,000 per day in water and sewer charges after deduction of the plant operating costs. The water is reused for cleaning, in scrubbers and in boilers.

Previously, the facility discharged all the wastewater to a municipal treatment plant at a rate of up to 0.5 mgd, and paid both volume and load charges

Quality Criteria

Since the plant produces a food product, ultimate water quality is vital. The two-stage membrane system (MBR + RO) and final sterilization with ultraviolet (UV) treatment provides the quality assurance that plant management requires. In addition, the membranes used in the MBR system are external to the aeration basin and are tubular. This type of membrane is much less susceptible to failure than the immersed type.

System Design

After a review of the available treatment options, the owners of the facility chose the Dynatec bioreactor option. This process combines aerated biological treatment with an out-of-basin ultrafiltration (UF) system. In combination with reverse osmosis treatment, Dynatec was able to provide the client with the necessary assurances that the water quality would not be compromised, and that the water would be suitable for process purposes, such as boiler feed water.

Dynatec’s design consisted of the following components:

- Internally fed rotary screen

- 500,000 gallon above-ground stainless steel equalization tank with jet aeration and duplex PD blowers

- 500,000 gallon above-ground stainless steel aerated biological reactor with jet aeration and triplex PD blowers

- Four membrane skids with a common automated CIP (clean-in-place) system, one skid operates in standby mode

- Reverse Osmosis system

- Final UV (ultraviolet) sterilization

- Sludge dewatering decanter centrifuge

- Completely integrated control system managing all system functions

System Advantages:

- The system provides many advantages for the operators and owners.

- Redundant membrane skids for ease of operation and cleaning.

- Simple automated cleaning operations with membranes in place.

- High mixed liquor concentration ensures the lowest possible sludge production, and requires smallest possible footprint.

- Simple, low maintenance system.

- Long-lasting tubular membranes with 0.03 μm membrane, ensuring removal of bacteria and viruses.

Results:

The system has produced high quality water for reuse. Consistently, the water quality from the MBR has been as follows:

| Analytic | Units | Influent | MBR Effluent |

| BOD5 | Mg/L | 1200 | <5 |

| COD | Mg/L | 20 | |

| TSS | Mg/L | No data | ND |

State Award

The facility received an award from the State of Georgia Association of Water Professionals presented an award to the

facility for Outstanding Operation of a facility in the category of Water Conservation.

Project Conclusion:

The project was completed on time and within budget, and has exceeded the estimates that were initially made for cost savings.

The Dynatec system has proved to be reliable and efficient, and has exceeded the customer’s requirements, based on the initial

projected performance.

Technology Benefits

Biological treatment using Membrane Bioreactors provides several benefits:

- Consistently high-quality water

- No upsets, since the membrane provides a positive barrier to bacteria and viruses

- Smaller footprint than conventional systems, due to operation at high levels of mixed liquor

- Better system kinetics than conventional systems, due to long sludge age

- Complete removal of bacteria and viruses

- High quality water for reuse

- Dynatec Out-of-Basin MBR Systems:

- Operators never come in contact with biomass

- Easy clean-in-place without moving membranes

https://www.dynatecsystems.com/industries/food-and-beverage/

Color Removal with Membranes

Color Removal with Membranes

Membranes selectively remove dissolved species from a variety of sources including:

- Surface water

- Rinse water from fabric dyeing

- Industrial wastewater

Landfill leachate

Landfill leachate

Demands for development of membranes with specific performance continue to increase as water quality requirements tighten and water treatment system designs become more complex. Such demands lead to development of new reverse osmosis (RO) and nanofiltration (NF) membranes with higher rejection characteristics for better dissolved salts and boron removal.

New applications have developed which require selective removal of certain dissolved species such as:

- hardness

- natural organic matter (NOM)

- pesticides

- Organic material which causes color

Engineers desire high removal of specific contaminants in these applications, but at the same time want to maintain some level of salts in the water so it does not become aggressive, which can cause corrosion problems with piping in the distribution network.

Nanofiltration (NF) membranes have good selectivity for removal of naturally occurring organic compounds as well as iron. Organic material can be found in groundwater sources which have surface water intrusion, or groundwater sources which are influenced by decomposing vegetative materials. The contamination of these waters is measured in terms of color units.

Treated water from landfill leachate is another source of color in wastewater. When this wastewater is discharged to a municipal treatment plant (POTW), color and the presence of certain organic acids affect the performance of the final ultraviolet treatment step, causing the receiving facility to require that these components be reduced or eliminated.

Dynatec has developed a number of options for color removal with membranes and organic acid removal. Since each project requires different levels of removal and has different treatment requirements, treatability work is typically carried out to establish the required treatment process steps. Typically, treatment requirements not only include color removal, but may also require the removal of COD, BOD, oil and grease, metals, etc. The treatment steps may include:

- metals and/or free-floating oil

- settleable materials removal

- ultrafiltration for removal of suspended colloidal materials

- nanofiltration using several options that are available, depending on the requirements of the particular application

- reverse osmosis for the removal of color, dissolved solids and organics

Finally, some color removal can be accomplished with ion exchange resins specially developed for color removal.

Dynatec will carry out treatability work at their treatment lab or will provide small-scale pilot equipment that is shipped to the project site where longer term studies can be carried out.

Contact us today to discuss your wastewater treatment needs.

www.dynatecsystems.com/industries/textile-wastewat…reatment-systems/

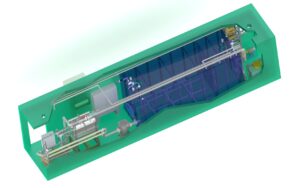

Containerized Membrane Bioreactor Systems

Containerized membrane bioreactor systems:

- Easy low-cost installation

- No building required

- Easily moved to other locations

- Quick and easy mobilization

Dynatec has extensive experience in the supply of containerized membrane bioreactor systems:

Treatment of up to 35,000gpd of sanitary waste in one container:

Needs minimal operator attention

- Uses long‐lasting out‐of‐basin tubular membrane

- Produces high-quality purified water

Dynatec’s containerized membrane bioreactor systems use tubular out-of-basin membranes.

This concept provides many advantages:

- The system has the ability to operate at much higher levels of MLSS than conventional systems and immersed MBRs.

- High levels of MLSS allow for higher levels of treatment, improved discharge quality, lower Waste Activated Sludge (WAS) volumes as well as increased flows from the same size reactor vessels.

- The concept is simple, requiring minimal operator attention.

- An available option allows for remote monitoring and/or control for even less operator attention.

- The system can be provided with aerobic digestion alone, or with nitrification/denitrification for total nitrogen removal.

- The system is provided complete with system feed pumps and screening installed.

- The membranes used provide up to 5-log levels of bacteria removal, reducing fecal discharge to non-detect levels.

- The effluent from the system is suitable for many non-potable uses, including irrigation and toilet flushing. The effluent is suitable for further treatment, such as reverse osmosis without the requirement of any pretreatment, since no suspended solids are present, and residual organics are present only at low concentrations.

The MBR has proven to be optimal for treatment of many industrial wastewaters because it is less susceptible to upsets. The MBR’s performance is not affected by changes in sludge settleability like the conventional systems, making MBR a wise choice for industrial systems that have more difficult to treat waste streams. Dynatec has over 44 years experience in dealing with difficult to treat industrial wastewaters using membrane filtration.

Contact Dynatec Systems today to discuss your wastewater needs.

Wastewater reuse

Wastewater reuse is achieved at an automotive plant. Wastewater equipment to treat both sanitary and production wastewater that included oily waste was designed and installed in a new transmission manufacturing facility. The goal was to treat and purify water for reuse.

wastewater that included oily waste was designed and installed in a new transmission manufacturing facility. The goal was to treat and purify water for reuse.

Dynatec met these demands by providing a membrane bioreactor (MBR) followed by a reverse osmosis (RO) system. The MBR reduced BOD, TSS, and oil and grease to non-detect levels. The RO is used to polish the MBR effluent so that it is suitable for reuse. It is reused in cleaning operations, cooling tower, and all production applications.

80%-90% of the wastewater is purified for reuse. Additional industrial park wastewater (after primary clarification at the industrial park) is introduced to the system for treatment and purification. The system is designed to receive 300,000gpd and purify 250,000gpd for reuse.

This novel approach greatly reduced the total amount of wastewater discharged by this plant. It provided the water needed for production using a comprehensive system that Dynatec designed, supplied and installed.

Ultrafiltration (UF), Membrane Bioreactor (MBR), Nanofiltration (NF) and Reverse Osmosis (RO) are employed by Dynatec for these wastewater projects. Wastewater recovery and reuse has been successfully implemented with industrial and sanitary wastewater streams for:

- Cooling tower make up

- Boiler feed

- Irrigation

- Toilet flushing

- Direct potable reuse

- Cleaning/wash applications

- Rinse processes

- Painting processes

- Other plant processes

For more information on wastewater reuse, please contact us today.

https://www.dynatecsystems.com/technologies/recovery-and-reuse/

Silver Recovery at Microcircuit Plant

The Problem

A microcircuit materials production facility produces high purity silver in their process. The process produces a wastewater stream containing valuable dissolved silver compounds. The plant had an existing membrane treatment system to recover the silver from the wastewater, but the system had performance problems, required excessive maintenance and chemical cleaning costs were high.

The Solution

When the plant expanded its operations, they performed an evaluation. The choice was between expanding the existing membrane system or installing a Dynatec membrane system designed for simple automatic operation with low operating costs. Dynatec was ultimately selected to provide a complete system because the Dynatec design offered a more reliable, easier to operate process. The installation includes transfer pumps, two reaction tanks, three ultrafiltration skids designed for 25 gpm each with room for expansion, a sludge conditioning system, and a filter press.

The Process

Wastewater from the process is stored in an equalization tank. Transfer pumps deliver the equalized wastewater to the first reaction tank where DTC (dithiocarbamate) is added to react with the aqueous silver compounds to form insoluble metal salts. The water then enters another reaction tank where the pH is adjusted to optimize precipitation of the silver compounds.

The precipitated silver compounds are then filtered in one of the three ultrafiltration skids. The ultrafiltration system, using tubular PVDF membranes are designed for automatic operation. When the membranes become fouled, the operator initiates an automatic cleaning, and the system performs a chemical membrane cleaning and the ultrafiltration skid is brought back into service.

The permeate from the ultrafilter is discharged and the concentrated silver is sent to a sludge conditioning tank where a high molecular weight cationic polymer is added to aid in filterability of the sludge. The sludge is then sent to a filter press and the cake is sent to a silver reclamation facility.

Conclusion

The installation of the new system was successful. The system has been operating for several years. Current operation at the plant consists of operating two filtration skids at a time with one as a standby. The system is designed to add capacity by simply adding membranes to the existing UF skids. Operators are happy with the system’s operation and the lower amount of maintenance and chemicals required.

Contact Dynatec to discuss your wastewater application.

https://www.dynatecsystems.com/industries/heavy-metals-removal/

High Quality Discharge MBR

Dynatec provides High Quality Discharge MBR system for Retirement Home

The retirement community consists of independent living homes and apartment homes in rural Maryland. The facility is in horse country, in a valley among rolling hills, and shares the area with high-end homes.

Previously, the facility had two septic tanks, and a recirculated sand bed filtration system. This created odors and caused mosquito infestations in summer. The facility chronically missed discharge limits, and thus was paying frequent fines. The sand bed filtration system was high maintenance, constantly flooding and requiring maintenance.

Replacement Criteria

In deciding on a replacement system, several criteria were important to the facility and to State regulators. The plant must be aesthetically pleasing. Odors must be minimized and if possible, eliminated. The plant had to achieve high levels of treatment to meet present and future discharge requirements. Future use of the treated water for irrigation is planned. The plant had to be operator friendly, and be capable of being monitored remotely, since full-time staff would not be available. The plant must be cost effective, from both capital and operating standpoints. Finally, the plant must be modular, in that future expansion of the facility must be accommodated in the design.

The initial plant sizing was nominally for 50,000 gallons per day of treatment capacity and has been expanded to 100,000 gallons per day.

System Design

After a review of the available treatment options, the owners of the facility decided on the (MBR) Membrane Bioreactor option. Due to the modular design of the system, they also chose the out-of-basin membrane module concept provided by the Dynatec MBR system. This process combines ease of use with all the requirements of both the owners and the regulators.

Odor control is achieved by using closed tanks vented to atmosphere. Air from the screening room is used to provide aeration to the reactors and the membranes, using the biomass as a biofilter. The negative pressure in the screen room ensures that there are no fugitive odors from the area. Mixing and aeration of the EQ tanks (the existing septic tanks) ensures no odors from that area.

Design Compatibility with the area: due to the nature of the area, the plant was designed to be installed in a “horse barn”, or at least a building that looks like a horse barn, but in fact, contains both the treatment plant and space for landscaping and other equipment.

High Levels of Treatment have been achieved since the plant’s inception in early 2007. Performance has been maintained since that time. Future plans include treatment for Total-N and Total-P to comply with Maryland’s “flush tax” requirements.

High Levels of Treatment have been achieved since the plant’s inception in early 2007. Performance has been maintained since that time. Future plans include treatment for Total-N and Total-P to comply with Maryland’s “flush tax” requirements.

Cost Effective Installation was achieved using standard above-ground HDPE tanks, rather than the more common concrete tanks

Plant Expandability was achieved by the installation of one half of the plant, and the addition of a second membrane rack. No modifications to tanks or other work were required in 2009.

Conclusions:

Since completion and startup in early 2007, the plant has reliably performed, always producing high-quality water.

The Dynatec MBR concept provides economic advantages due to the modular design and the use of standard tanks. The cost of operation is modest when compared to alternatives.

Contact Dynatec Systems today to discuss your sanitary wastewater solution.

https://www.dynatecsystems.com/industries/sanitary-wastewater/

Decentralized Wastewater Treatment Facility

Dynatec provided the membrane system for a demonstration plant situated directly adjacent to the Anaheim, CA City Hall. The system is designed to pump wastewater from a local sewer line, treat the wastewater for reuse, and return the waste activated sludge and screenings to the sewer line.

The DynaLift™ out-of-basin membrane system was selected because:

- The high flux rates achieved by the DynaLift™ system allowed for a small footprint

- High MLSS concentrations allows for smaller reactor tanks

- The positive filtration achieved with MBR provides consistent high-quality discharge

- The out-of-basin design allows for better demonstration of the technology

- The membrane construction allows for high removal of bacteria and virus – demonstrated 5-log removal of bacteria and 4-log removal of virus.

The plant design is for two trains with the first train presently installed. The design flow of this plant is 75,000 gallons per day, and due to internal water uses, such as screen flushing, the net output of the final plant when fully installed will be 104,350 gallons per day. The recycled water is used for irrigation and toilet flushing within the requirements of California’s Title 22 Regulations.

Plant automation design allows for periodic operator attention only when equipment maintenance or chemical refilling is required.

Following treatment in the MBR, the effluent is further treated using ozone followed by UV for ozone destruction and chlorine addition at 1 mg/L to ensure no re-growth in the final effluent.

Following treatment in the MBR, the effluent is further treated using ozone followed by UV for ozone destruction and chlorine addition at 1 mg/L to ensure no re-growth in the final effluent.

Due to the proximity of City Hall and the fact that the plant is in a highly populated area, a state-of-the-art odor control system was installed. With the standard Dynatec design odor control is not typically required.

This is the first facility in California to use external MBR membranes, ozone and chlorination for water recycling. The use of decentralized wastewater treatment facilities is increasing and the City of Anaheim is in the forefront of this.

Contact Dynatec Systems today to discuss your wastewater reuse project.

https://www.dynatecsystems.com/industries/sanitary-wastewater/

MBR for Cereal Manufacturer

MBR for Major Cereal Manufacturer

Dynatec provides a turnkey wastewater solution for a food manufacturing wastewater process.

The problem

A major cereal manufacturing plant needed to upgrade their treatment process. MBR was selected, and the company was about one month away from entering into a contract with a major MBR supplier of submerged hollow fiber membrane bioreactors. The cereal manufacturer has had chronic problems in procuring wastewater treatment systems that were able to meet required treatment levels.

Dynatec was invited to offer a proposal based upon our previous experience and successful implementation of membrane bioreactor systems in the food industry. Specifically, Dynatec had previously installed a MBR system at another cereal manufacturing plant, which was operating without problems.

The Solution

When the two MBR systems were evaluated, Dynatec was selected. Reasons for selection were Dynatec’s experience with industrial wastewater, Dynatec’s record of success with other industrial MBR projects in the industry, lower cost and simpler operation.

Implementation

The system had one major requirement. It had to provide reliable operation without a long process of evaluating problems and making changes to the system. For this reason, the MBR process was used for its very reliable simple operation. A DAF was also provided by Dynatec ahead of the MBR system to remove solids and some BOD.

DAF effluent enters the MBR system for biological treatment and removal of solids. Some of the MBR effluent is reused on site for irrigation and other non-process uses. The other portion of MBR effluent is sent to a reverse osmosis system also provided by Dynatec. The RO effluent is used for cooling towers and other non-food reuse applications within the plant.

Dynatec was also engaged to install the system at the customer’s facility.

Contact Dynatec Systems today to discuss your wastewater application.

https://www.dynatecsystems.com/industries/food-and-beverage/cereal/