Automotive Connectors Manufacturer

A leading automotive connectors manufacturer was in need of a wastewater treatment system to address oil and grease and  heavy metal contaminants in their discharge. Based on understanding of the waste stream and ability to provide a cost effective solution, Dynatec was selected to provide a system that would produce effluent that reliably met the sewer discharge requirements. By using a combination of free oil separation and an Ultrafiltration Membrane system, in addition to removing all of the suspended solids, the Dynatec supplied system consistently provides the following effluent:

heavy metal contaminants in their discharge. Based on understanding of the waste stream and ability to provide a cost effective solution, Dynatec was selected to provide a system that would produce effluent that reliably met the sewer discharge requirements. By using a combination of free oil separation and an Ultrafiltration Membrane system, in addition to removing all of the suspended solids, the Dynatec supplied system consistently provides the following effluent:

Parameters Influent Effluent

Oil and Grease 1,100 <100

Zinc 2.4 <1.48

Chromium 3.2 <1.7

Automotive Solutions Provided

- Oil and metals removal

- Membrane Bioreactor (MBR) biological treatment

- MBR for water reuse of wastewater

- High purity reuse with MBR and RO

Complete purification and reuse of wastewater system solutions for many automotive firms were provided by Dynatec Systems for:

- Cooling tower makeup

- Irrigation

- Boiler feed

- Paint line

Contaminants Removed

- Oil and Grease

- Metals

- Suspended Solids

- Surfactants

- Biochemical Oxygen Demand (BOD)

- Chemical Oxygen Demand (COD)

- Dissolved Solids

Automotive oily wastewater treatment systems for many facilities in the automotive industry were designed and supplied by Dynatec Systems including the following:

- Stamping plants

- Powertrain plants

- Assembly plants

- Bearing manufacturer

Our customers include many large car and truck brands as well as suppliers to those manufacturers.

Ultrafiltration offers the following advantages over conventional separation:

- No chemical required

- Very little labor required

- Simple mechanical process

- Less sludge

- Ability to concentrate the retentate for beneficial use

- Less space required

- Overall lower operating costs

Tubular Configuration:

- Higher permeate rate

- Lower rates of fouling

- Higher concentration of retentate

- Easier to clean

- Longer membrane life

- Low operating cost

Ultrafiltration is a pressure-driven process that removes the following from wastewater and other solutions:

- Emulsified oils

- Metal hydroxides

- Colloids

- Emulsions

- Dispersed material

- Suspended solids

- Other large molecular-weight materials

Ultrafiltration systems are also capable of concentrating:

- Bacteria

- Some proteins

- Some dyes

- Colloidal or emulsified components

For more information, please contact us today.

https://www.dynatecsystems.com/technologies/recovery-and-reuse/

https://www.dynatecsystems.com/technologies/membrane-technologies/ultrafiltration-systems/

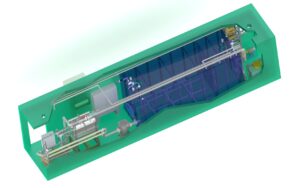

Containerized Membrane Bioreactor Systems

Containerized membrane bioreactor systems:

- Easy low-cost installation

- No building required

- Easily moved to other locations

- Quick and easy mobilization

Dynatec has extensive experience in the supply of containerized membrane bioreactor systems:

Treatment of up to 35,000gpd of sanitary waste in one container:

Needs minimal operator attention

- Uses long‐lasting out‐of‐basin tubular membrane

- Produces high-quality purified water

Dynatec’s containerized membrane bioreactor systems use tubular out-of-basin membranes.

This concept provides many advantages:

- The system has the ability to operate at much higher levels of MLSS than conventional systems and immersed MBRs.

- High levels of MLSS allow for higher levels of treatment, improved discharge quality, lower Waste Activated Sludge (WAS) volumes as well as increased flows from the same size reactor vessels.

- The concept is simple, requiring minimal operator attention.

- An available option allows for remote monitoring and/or control for even less operator attention.

- The system can be provided with aerobic digestion alone, or with nitrification/denitrification for total nitrogen removal.

- The system is provided complete with system feed pumps and screening installed.

- The membranes used provide up to 5-log levels of bacteria removal, reducing fecal discharge to non-detect levels.

- The effluent from the system is suitable for many non-potable uses, including irrigation and toilet flushing. The effluent is suitable for further treatment, such as reverse osmosis without the requirement of any pretreatment, since no suspended solids are present, and residual organics are present only at low concentrations.

The MBR has proven to be optimal for treatment of many industrial wastewaters because it is less susceptible to upsets. The MBR’s performance is not affected by changes in sludge settleability like the conventional systems, making MBR a wise choice for industrial systems that have more difficult to treat waste streams. Dynatec has over 44 years experience in dealing with difficult to treat industrial wastewaters using membrane filtration.

Contact Dynatec Systems today to discuss your wastewater needs.

https://www.dynatecsystems.com/technologies/membrane-bioreactors/mbr-conversion-r…pgrade-solutions/

Tank Truck Wash Water

A tanker truck operator built a new operations terminal part of which contains a wash facility to wash the interiors of trucks and the exterior of the tankers and tractors. The operation is a contract hauler so a wide variety of liquids will end up in the wastewater.

The facility obtained a sewer discharge permit that had restrictive oil and grease and metals limits but also had a daily discharge volume limit of 7,000 gallons.

Among the commodities transported are oil products, sugar, chemicals, acid, and caustic, as well as many other organic products. The system design, therefore, had to accommodate all these potential contaminants in the water.

The system design includes free oil separation, pH control and final treatment using ultrafiltration (UF). This treatment was designed to treat the wastewater to meet the sewer discharge limits despite variations in the waste stream.

Water having had the free oil, suspended solids, and emulsified oils removed and having had the pH controlled is suitable for use as wash and first rinse water in the tank washing operations. This, therefore, became part of the system design to conserve water and to enable the facility to meet the sewer volume discharge limitation. Because this was a new facility, there was not an opportunity to complete treatability studies on the wastewater. Dynatec Systems prior experience in similar/like applications served as the basis of design.

Tank Truck Wash Water Ultrafiltration

The ultrafilter is configured in a crossflow (tangential) flow process, a membrane pore size of 0.07 micron. It is used to reject colloidal and emulsified components in water. A high rate of flow across the membrane is maintained to cause turbulence. This, in turn, prevents fouling of the membranes.

For many waste applications like this one, a tubular membrane is specified to prevent the possibility of plugging of the membrane element and to concentrate the contaminants to a high concentration.

Tank Truck Wash Water Results

The system continues to meet the demanding discharge requirements. About 50% of the water produced is reused for wash and first rinse, both for the interiors of the tankers and for the exteriors of the vehicles.

The system is simple to operate and maintain. Variations in the quality of water being fed to the system caused by different chemicals being cleaned from the tankers does not cause variations in the quality of discharge.

Contact Dynatec Systems today to discuss your wastewater application.

https://www.dynatecsystems.com/technologies/membrane-technologies/ultrafiltration-systems/

Complete membrane filtration system

Complete membrane filtration system for a commercial wastewater treatment company provided by Dynatec Systems. The system gives them the ability to meet demanding requirements for discharge with the tubular ultrafiltration (UF) systems followed by two stage reverse osmosis (RO). They can safely meet the requirements for PFAS, 1-4 dioxane, heavy metals, chemical oxygen demand (COD) and total dissolved solids (TDS).

Complete membrane filtration system for a commercial wastewater treatment company provided by Dynatec Systems. The system gives them the ability to meet demanding requirements for discharge with the tubular ultrafiltration (UF) systems followed by two stage reverse osmosis (RO). They can safely meet the requirements for PFAS, 1-4 dioxane, heavy metals, chemical oxygen demand (COD) and total dissolved solids (TDS).

Membrane Technologies

Membrane Technologies have several membrane configurations available for Membrane Bioreactor (MBR) applications. Project requirements should drive the decision for membrane selection.

Technologies available for use in MBRs:

- Tubular

- Hollow Fiber

- Flat Sheet

Tubular Membranes

The original and most proven type of ultrafiltration is tubular membranes:

- Sturdy construction

- Long membrane life

- High flux rates

Of all membrane types, they are more robust and can be subjected to high pressures in demanding applications.

Out-of-Basin MBR is a configuration where mixed liquor is pumped at high velocity through the tubular membrane module. The high velocity continuously scours the membrane surface and prevents solids from building up. This process produces high flux rates and simple operation. No backwash is required. Lowest capital cost option because of the high flux rates and simple operation. Out-of-Basin MBRs by Dynatec are designed so that the energy requirements are equal to other types of MBR systems.

Advantages

- Higher performance due to higher MLSS and long sludge age

- Low Cost

- Simple Operation

- Entire system may be placed indoors

- Membrane tank not required

Hollow Fiber Membranes

They are constructed of a microporous structure having a dense selective layer on the outside surface. Many fibers must be packed into bundles and potted into tubes to form a membrane module. The surface area of even a few square feet require miles of fibers. Modules must contain no defective or broken fibers, therefore production requires strict quality control.

These membranes can withstand very high pressures from the outside, but are limited on pressure exerted from the inside of the fiber, therefore backwash rates are limited to around twice the normal permeate rate. The feed fluid is applied on the outside of the fibers and the permeate is removed down the fiber bore.

Hollow Fiber membranes are applied in clean water applications and are used in MBRs, but are limited to lower concentrations of solids than the other membrane types.

Advantages

- Low Energy

- Membrane Space efficient for large installations >5 MGD (million gallons per day)

- Cost effective for large installations

Disadvantages

- Not Cost Effective for small plants

- Membranes damaged easily

- More complicated system

- Cannot operate with high MLSS

For more information on membrane filtration systems, please contact us today.

#MBR, #UFRO, #UFMBR