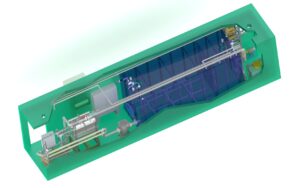

Containerized membrane bioreactor systems:

- Easy low-cost installation

- No building required

- Easily moved to other locations

- Quick and easy mobilization

Dynatec has extensive experience in the supply of containerized membrane bioreactor systems:

Treatment of up to 35,000gpd of sanitary waste in one container:

Needs minimal operator attention

- Uses long‐lasting out‐of‐basin tubular membrane

- Produces high-quality purified water

Dynatec’s containerized membrane bioreactor systems use tubular out-of-basin membranes.

This concept provides many advantages:

- The system has the ability to operate at much higher levels of MLSS than conventional systems and immersed MBRs.

- High levels of MLSS allow for higher levels of treatment, improved discharge quality, lower Waste Activated Sludge (WAS) volumes as well as increased flows from the same size reactor vessels.

- The concept is simple, requiring minimal operator attention.

- An available option allows for remote monitoring and/or control for even less operator attention.

- The system can be provided with aerobic digestion alone, or with nitrification/denitrification for total nitrogen removal.

- The system is provided complete with system feed pumps and screening installed.

- The membranes used provide up to 5-log levels of bacteria removal, reducing fecal discharge to non-detect levels.

- The effluent from the system is suitable for many non-potable uses, including irrigation and toilet flushing. The effluent is suitable for further treatment, such as reverse osmosis without the requirement of any pretreatment, since no suspended solids are present, and residual organics are present only at low concentrations.

The MBR has proven to be optimal for treatment of many industrial wastewaters because it is less susceptible to upsets. The MBR’s performance is not affected by changes in sludge settleability like the conventional systems, making MBR a wise choice for industrial systems that have more difficult to treat waste streams. Dynatec has over 44 years experience in dealing with difficult to treat industrial wastewaters using membrane filtration.

Contact Dynatec Systems today to discuss your wastewater needs.